The Importance of a Smart Automation Certification

To view this as a Multimedia Presentation, please click here.

It’s no secret the immense role that Industry 4.0 is expected to play in the future of industrial manufacturing.

Industry 4.0, or the 4th Industrial Revolution, is bringing a new wave of digital technology, such as artificial intelligence (AI), cloud computing, the Internet of Things (IoT), and augmented/virtual reality (AR/VR) to make businesses more accurate, efficient, and productive, all while lowering the cost of doing business.

However implementing the process isn’t as easy as the snap of a finger.

While technologies continue to advance by the day, employing skilled workers to operate, maintain, and troubleshoot these machines is becoming more arduous. Employers are having difficulty finding qualified candidates that possess the necessary hands-on skills and knowledge needed for these modern, advanced jobs.

SACA, the Smart Automation Certification Alliance, noticed the issues that were plaguing industry leaders. The non-profit organization, based out of Louisville, Ky., decided to make it their mission to develop and deploy modular Industry 4.0 certifications for a wide range of industries.

These standards and certifications focus on “connected systems” skills that address the integration of smart components and other Industry 4.0 technology in order to increase the number of individuals who possess the competencies needed by employers.

Jim Wall, SACA’s Executive Director, knows how important a Smart Automation certification can be in today’s ever-changing workforce, and what it can mean for your school or organization.

Q: What was the initial thought behind beginning a non-profit that focuses on Industry 4.0 credentialing?

Jim Wall (JW): “Based on testimonials from both industrial and educational leaders around the world, we noticed a common issue that nearly everyone was experiencing: the critical shortage of highly skilled workers. And with no viable solutions available, we decided to create our own. SACA brought together industry leaders to develop the standards, or requirements, that Industry needs for these emerging Smart Factories. These standards established the guidelines for training programs wishing to provide their students with Industry 4.0 skills. Along with developing the standards, industry leaders worked with SACA to develop a series of certifications to provide nationally recognized validation of their skills. The overall goal of these efforts was to facilitate the development of a pipeline of skilled talent from within communities.”

Q: Can you explain a little more about your certifications?

JW: “Each SACA certification is stackable, meaning students can start with one certification and add others later to customize their skills. They are also occupationally-focused, so they validate actually Industry 4.0 skills needing on the job, instead of being focused on a particular brand of machine or component, which is the focus of most other certifications. SACA certifications start at the Associate Level and focus on operations, robot systems, and other tasks. From there, students advance to the Specialist Level certifications that focus on troubleshooting, programming, maintaining, and integrating systems. In this level, they can also earn micro-credentials along the way. Core micro-credentials allow learners to earn credentials in specific areas of learning, which certify skills applicable to all companies while elective micro-credentials can be added to match regional or specific company needs. Finally, the Professional Level is an engineering-level certification that builds on the Associate and Specialist credentials.

Q: What separates SACA’s Industry 4.0 credentials from those offered by other companies?

JW: “What’s unique about SACA is that our certifications cover all the tasks encountered in an Industry 4.0 occupation, like the blending of IT and manufacturing skills, which is absolutely essential in modern smart factories. Most other certifications focus on one particular task or a specific brand of equipment. SACA pulled together industry leaders, from various types of manufacturing, that had the expertise required to develop standards and certifications for the occupations encountered in Industry 4.0 occupations. No other certification organization has done this.

Another difference is SACA’s micro-credentials. While other organizations have certifications that take months to prepare for, SACA’s micro-credentials can be quickly earned and used to acquire a rewarding job while the individual continues to work towards additional credentials.”

Q: You mentioned working with ‘industry leaders’. Who are some of the recognizable industrial companies that you work with?

JW: “All of our standards and certifications are developed by technical experts from all types of industries on a voluntary basis. Leaders from these companies recognized the value in the standards and certifications being developed by SACA, and invested their time and expert knowledge to guide and shape the certifications to truly meet what industry needs. Specifically, we work very closely with FANUC and Rockwell Automation to create and develop these standards for validation. But those aren’t the only two – we also work with other companies including Ashley Furniture, Boeing, Foxconn, Hershey, Kohler, and many more. Honestly, seeing these highly-knowledgeable and respectable professionals coming together in SACA’s workshops to develop Industry 4.0 standards was truly an amazing experience. This incredible commitment they demonstrated to be a part of this process shows the importance they place on these credentials.”

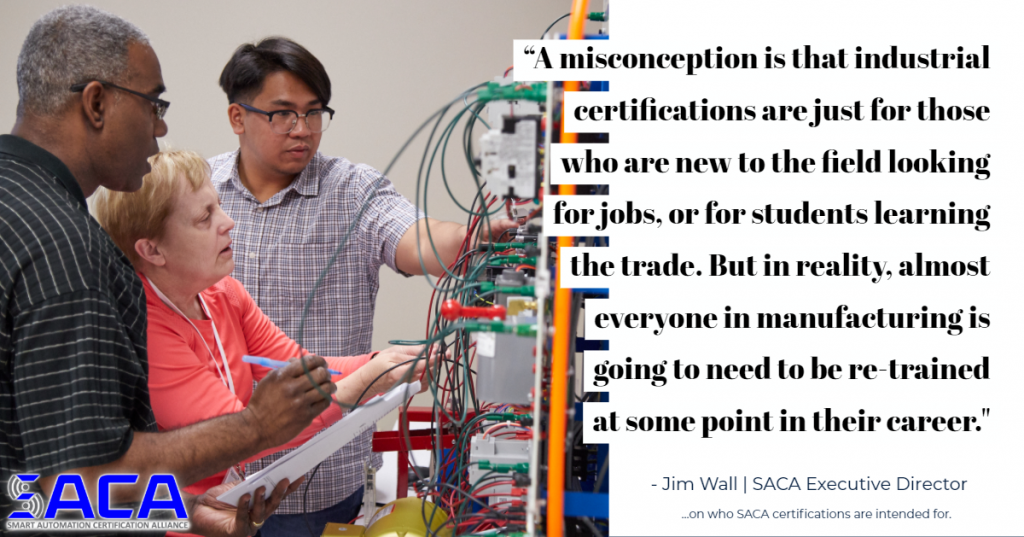

Q: Who are these certifications intended for?

JW: “Anyone planning to enter the manufacturing workforce and those that are already in a manufacturing career. A misconception is that industrial certifications are just for those who are new to the field looking for jobs, or perhaps for students learning the trade. But in reality, almost everyone in manufacturing is going to need to be re-trained at some point in their career. Jobs are changing. A study I saw recently by McKinsey Institute estimated between 75-375 million people will have to learn new skills by 2030 due to the changing workforce. That’s staggering. So with that said, we want these companies to be able to quickly identify if an individual has the right skill set to work in an Industry 4.0 environment. So SACA’s certifications are intended to give Industry the proof that these individuals not only have the skills, but the student can also show proof of their hard work in obtaining those skills.”

Q: Why should schools partner with SACA? What benefits will they get from the partnership?

JW: “For all of our high school and college education members, they have the opportunity to provide their students with positive proof of their Industry 4.0 skills using SACA’s certifications. By providing proof of a SACA credential – a credential, if I might add, that carries heavy weight in the industrial sector – immediately gives learners a leg-up in the hiring process by simply having a SACA certification, thanks in large part to those industry leaders who helped create our standards. As a member of SACA, educational organizations can certify an unlimited number of individuals with zero cost to the student.

“By providing proof of a SACA credential – a credential, if I might add, that carries heavy weight in the industrial sector – immediately gives learners a leg-up in the hiring process.”

In addition to credentials, though, these companies that have invested their time and effort want to see how its participants are performing. So your school and program will be firmly on the radar for the FANUCs and Rockwell Automations of the world, vaulting your program’s visibility both locally and nationally. Advertising your program as a SACA Certification Site not only attracts interest from local industries, but it also works as a great recruiting tool to attract incoming students.”

Q: What can SACA do for Industry?

JW: “It’s pretty much the same as schools, but with a few different options. We have varying levels for Industry involvement, which can be catered to fit individual company size. However the fact remains that there is a skills gap out there and those positions need to be filled by individuals with the right skill set. But right now, it is extremely difficult to find those people. So probably the best benefit that we can offer industries is what our whole concept is about – verifying that individuals have the proper set of skills for Industry 4.0 So by becoming a SACA member, it allows you to help provide this certification process in your local areas.”

Q: What does the cost of a SACA membership?

“When we discussed starting SACA, one of the major pitfalls we noticed was that other certification organizations charge a substantial fee to the person taking the certification exams. This is a huge barrier for some students. So we made the decision to do something different. SACA’s Educational memberships have a very low membership fee and this membership includes an unlimited number of certifications that they can provide to their students at zero cost. Industry Memberships are available in multiple levels to better suit an organization’s needs.”

Q: What are SACA Pilot Organizations?

JW: “We are actually looking for Pilot Organizations for SACA certifications. Pilot Organizations help us test and refine our certifications process. Basically, we’re searching for both Schools and Industry to be one of the first programs to have their learners earn Industry 4.0 certifications. Those that are selected as a Pilot Organization will get free certification testing and first access to our industry-validated certifications. In exchange, Plus, all of the companies that helped develop the standards to which the certifications were created will be paying a lot of attention to students and organizations participating in the piloting program, which is an excellent way to increase the partnership between schools and industry. So it’s definitely a ‘scratch my back, I’ll scratch yours’ type of partnership that should benefit all parties, but especially the students.”

Q: If anyone is interested, how do they become a Pilot Organization?

JW: “Well SACA’s website, www.SACA.org, is a great place to start. There are links there for more information, how to sign-up, and anything else one might need. Our Help Desk Specialist will also be doing free webinars on Wednesday mornings in September. But our emails are always open, and we are more than happy to assist in any way that we can. I would also invite everyone to follow us on social media. In addition to the website, you can also find SACA on Facebook, Twitter, LinkedIn, and YouTube.